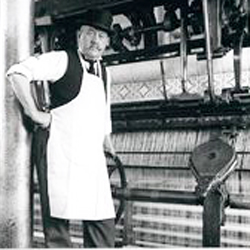

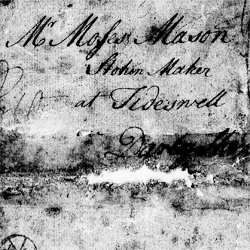

The Mason family were already framework knitters and flax dressers by the 1730s and started making lace when this fabric was first produced by machines in the 1760s, at the start of the Industrial Revolution.

Throughout these two centuries close attention to detail has always brought the company to the forefront of new technology.

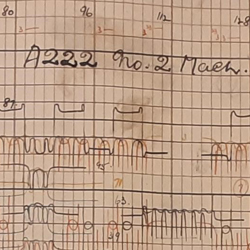

Throughout the last one hundred and fifty years Cluny Lace has continued to build up a data bank of hundreds of lace patterns.

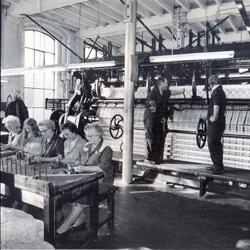

By combining the best of old traditions with new technology the firm is able to produce a wide range of exquisite designs of Leavers Cluny style lace allovers, edgings and insertions and Leavers Fine Cotton Valenciennes style lace allovers, edgings, galloons and insertions.

Many of the lace patterns still used today were designed and draughted by Frank Maltby Mason and Francis Bowler Mason, the sixth and seventh generations of the family.

No other manufacturer in the world produces the same range of patterns and these patterns are unique to Cluny Lace Company Limited

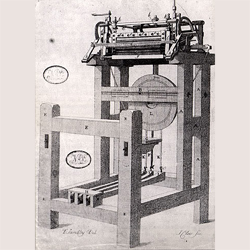

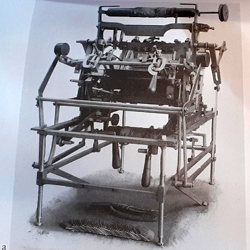

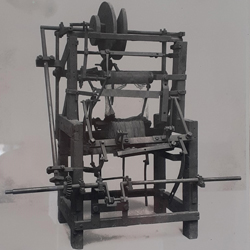

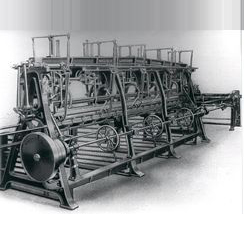

For those with a historic or mechanical interest a Leavers machine is in fact two machines; a wide machine working on the principle invented by Mr. John Leavers in 1813 twist together the threads to form a fast net, and a jacquard machine, adapted for use on the Leavers machines between 1836 and 1841, puts in the patterns.

The jacquard machine is attached to the Leavers machine by between 60 and 160 steel bars each 4/1000 of an inch in thickness and it is through these steel bars that the warp threads are threaded at intervals. Instructions as to the movement of the steel bars/warp threads are given by a pack of laced cardboard cards punched with holes which revolve around a cylinder, and whose concept were the inspiration of modern computer technology.

The lateral movement of these warp threads is held fast and twisted by the bobbin threads of the Leavers machine and turns the basic net into exquisite patterns.